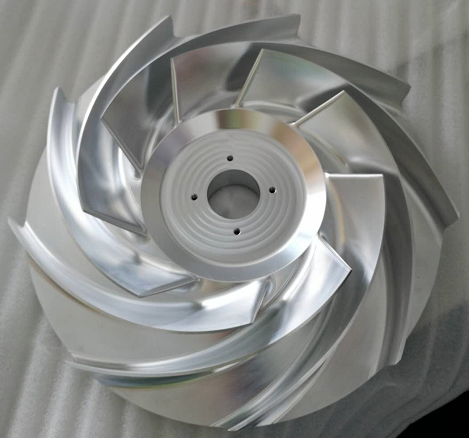

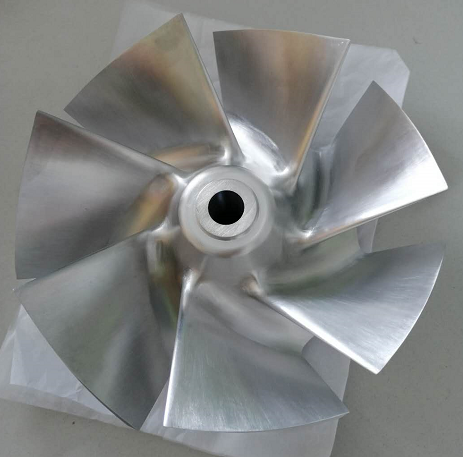

3-Axis and 5-Axis Machining

Two distinct “flavors” of milling exist at HUAYU. With 3-axis machining, the work piece is gripped from the bottom of the raw material blank while all of the part features are cut from up to 6 orthogonal sides. With parts larger than 10 in. by 7 in. (254mm by 178mm), only the top and bottom can be machined: no side setups! With 5-axis indexed milling, however, machining from any number of non-orthogonal sides is possible.

The tool sets used in either case are identical. What’s different is the raw material. As with HY lathes, some precised parts are used for 5-axis milled parts, which presents some interesting mathematical discussions about the size, geometry, and positioning of the part within that raw material volume. For some examples of this, you can send your design via website www.hy-prototypes.com or email info@hy-prototypes to have free consultant with our engineers.

Found out the best solution for your design build up. Huayu team will fulfil your design into real life with the most suitable manufacturing processes.