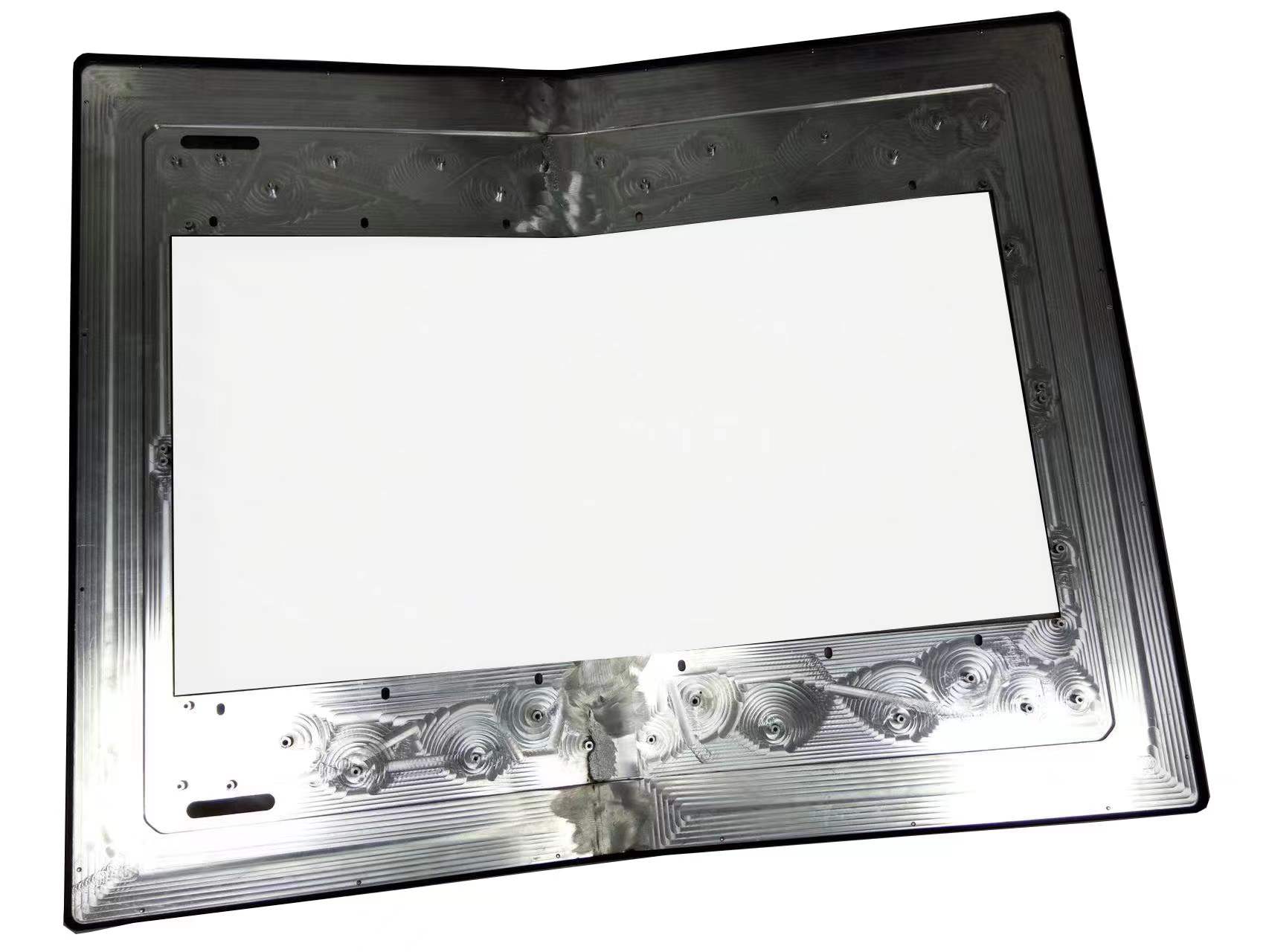

CNC processing prototype for wagering equipment

- Material Used: Aluminium 6061 T6

- Number of Cooperation:1 set

- Production Process Used: CNC Machining

- Production Cycle:7 days

3D Printing for Motor Bike Parts Prototype Case

- Material Used:ABS + Metal Thread Insert + Aluminium Gear

- Number of Cooperation:1 set

- Production Process Used:3D printing technology + CNC Machining

- Production Cycle:7 days

High-end Luxury Bentley Car Air-conditioning Vent Outer Ring And Other Car Accessories

- Material Used:304 stainless steel

- Number of Cooperation:5 batches per year, 50 pieces per batch

- Production Process Used:Three-axis CNC turning pin processing, four-axis CNC milling processing, mirror polishing post-processing

Lidar IMUX-SP1 Box

- Material Used:Aluminum alloy 50552

- Number of Cooperation:3 sets total 3

- Production Process Used:Sheet metal bending, riveting, welding, Alodin chemical conversion, surface spraying, silk screen printing

- Production Cycle:10 days

Case of Internal Reinforcement of Smart Game Console

- Material Used:PA+30%GF

- Number of Cooperation:8 sets, 24 parts in total

- Production Process Used:SLS 3D printing technology

- Production Cycle:7 days

Jewelry Identification Mirror Case

- Material Used:PMMA

- Number of Cooperation:30 sets total 30

- Production Process Used:CNC turning, CNC milling, Surface plating

- Production Cycle:15 days

Projects

All our cases are from the customer's permission, to show everyone our manufacturing process. We still have a lot of better professional cases, but we didn't show them without the customer's consent. If you need to know more about technical knowledge or want to know more about our company’s quality control process, and our delivery guarantee system, please contact us, we will do you provide a full range of consulting services!

Our advantage

Professional technology, fast delivery

16 years of professional experience in rapid prototyping and product development; flexible and fast production, can meet different order quantity requirements and can make corresponding emergency planning according to customers' demand for delivery.

Stable product, advanced equipment/process

All production links are in accordance with ISO 9001 standardized operation, multi-level quality control; advanced production equipment is an effective guarantee for dimensional accuracy, and perfect post-processing technology makes the product more perfect.

Cost-effective

One-stop production is one of the most effective ways to effectively reduce and control costs; a batch pass rate of more than 98% can better reduce production costs and save costs for customers.

Taking customer satisfaction as the purpose

We not only produce prototypes and parts, we pay more attention to the customer's ordering experience and the realization of ideas. Actively respond to customer needs and deliver samples within 24 hours of working days; from the order to the product delivery to your door, we will take care of every step of your order completion, and the delivery rate can reach 99%.