Production Case of Intelligent Air Conditioning Equipment for Air Conditioning

According to your project needs, CNC service can solve various problems for you. If you would like to know more about technology and prototyping services, please call us. We are glad to provide you with professional and efficient service.

- Materials Used: Engineering ABS white, POM, aluminum alloy, 304 stainless steel

- Number of Cooperation: 60 sets of 1500 parts

- Production Process Used: CNC machining, wire cutting, post-processing

Project Details

Cooperation Premise

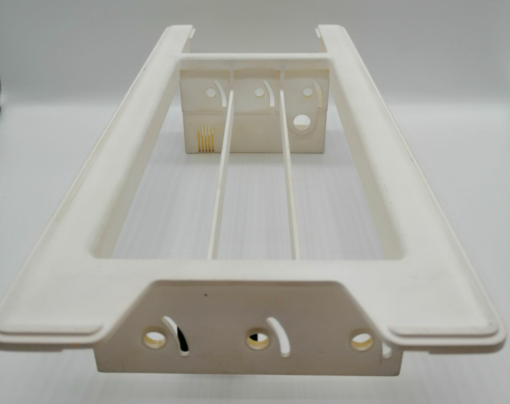

This is a technology company from Switzerland. The company needs to develop a smart home series to control the air volume of the central air conditioning outlet to suit the temperature requirements of each area. This product is first sampled in small batches in the early stage, so as to reach the market quickly, and then collect feedback from the market to prepare for mass production. Customers have very high requirements for the processing precision of the parts of the product and the strength of the parts, so as to ensure the smooth operation during the opening and closing process without noise. Because it is small-batch production, the customer's requirement is that the cost must be controlled to the lowest range and delivery must be completed quickly.

About the Project

Through cost accounting and process analysis, we have worked out the coordination of CNC machining + wire cutting + and post-processing of personnel. After a variety of supplier evaluations, the customer finally chooses to cooperate with us.

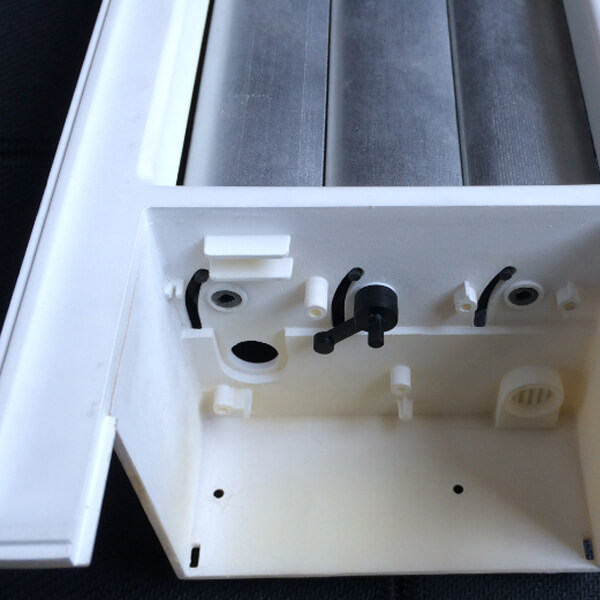

CNC Machining

The main components of the product are ABS and POM materials. The ABS material has good strength and is easy to be colored on the surface to make it look beautiful. However, during the processing, attention should be paid to prevent the cutting from overheating and affecting the surface processing effect.

During the processing, we use air and water cool down. In order to achieve the strength of the parts, the use of 5-axis CNC machining is the most ideal, so that the overall processing of the parts can be completed.

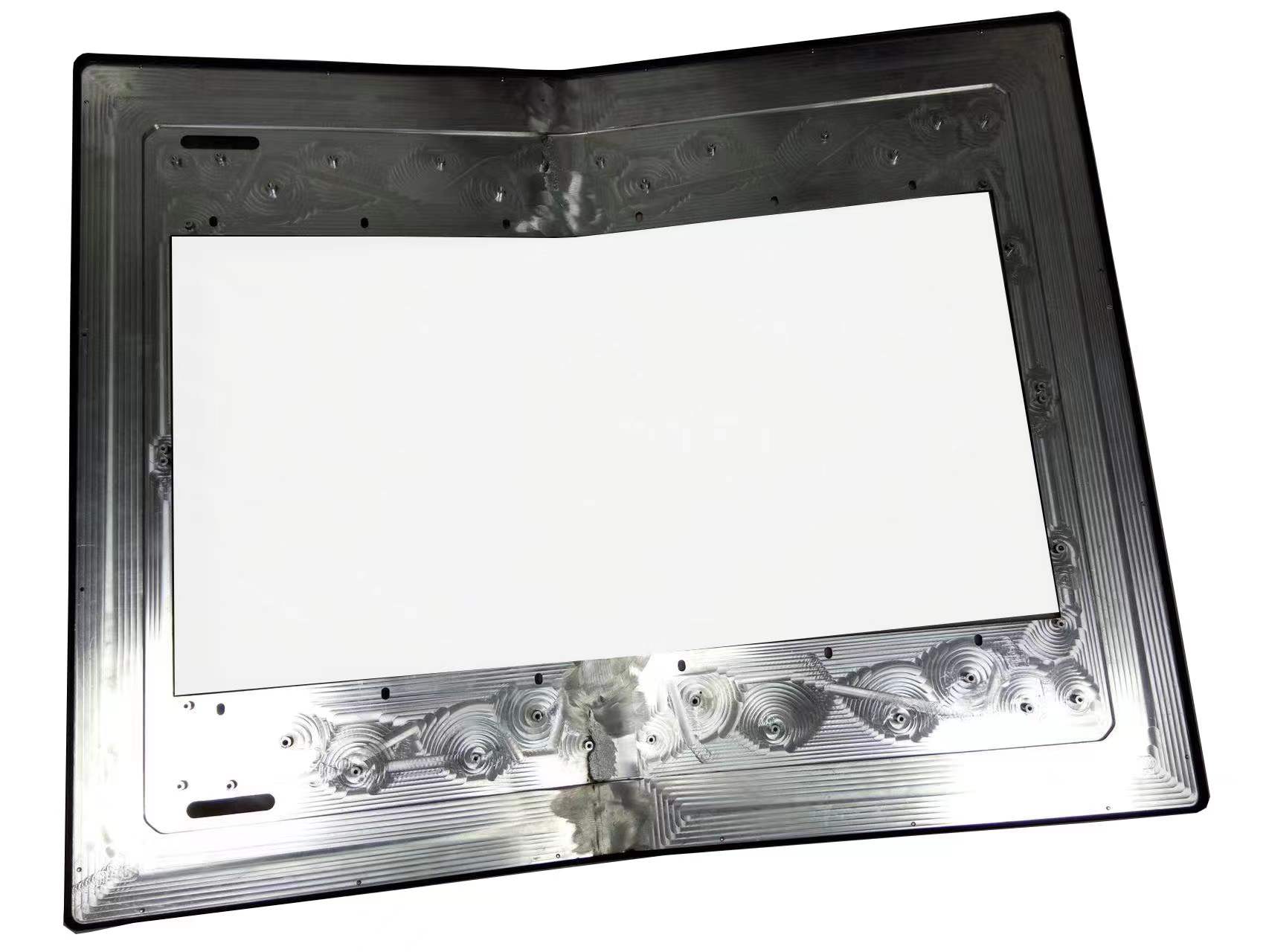

Wire Cutting Machining

The wall thickness of aluminum parts is too thin to be the only 0.35mm, and the shape and assembly are complicated. We use wire cutting to ensure the accuracy of the product, the product will not be deformed, and the processing time will be faster.

Quality Inspection

Our QC department uses a three-coordinate measuring instrument to measure the actual size of the processed parts to check the consistency of the entire batch of parts to ensure compliance.

Post-processing

We perform surface polishing and painting on qualified parts and anodize the surface of aluminum parts with natural colors so that the products can achieve a more perfect appearance.

Experience

The most fundamental reason why we can satisfy customers is the advantage of cost performance, professional understanding of customer ideas, and fast delivery. These three elements are the conditions for customer satisfaction. If you happen to have a project to solve, please contact us in time, you can get free professional analysis and cost control.