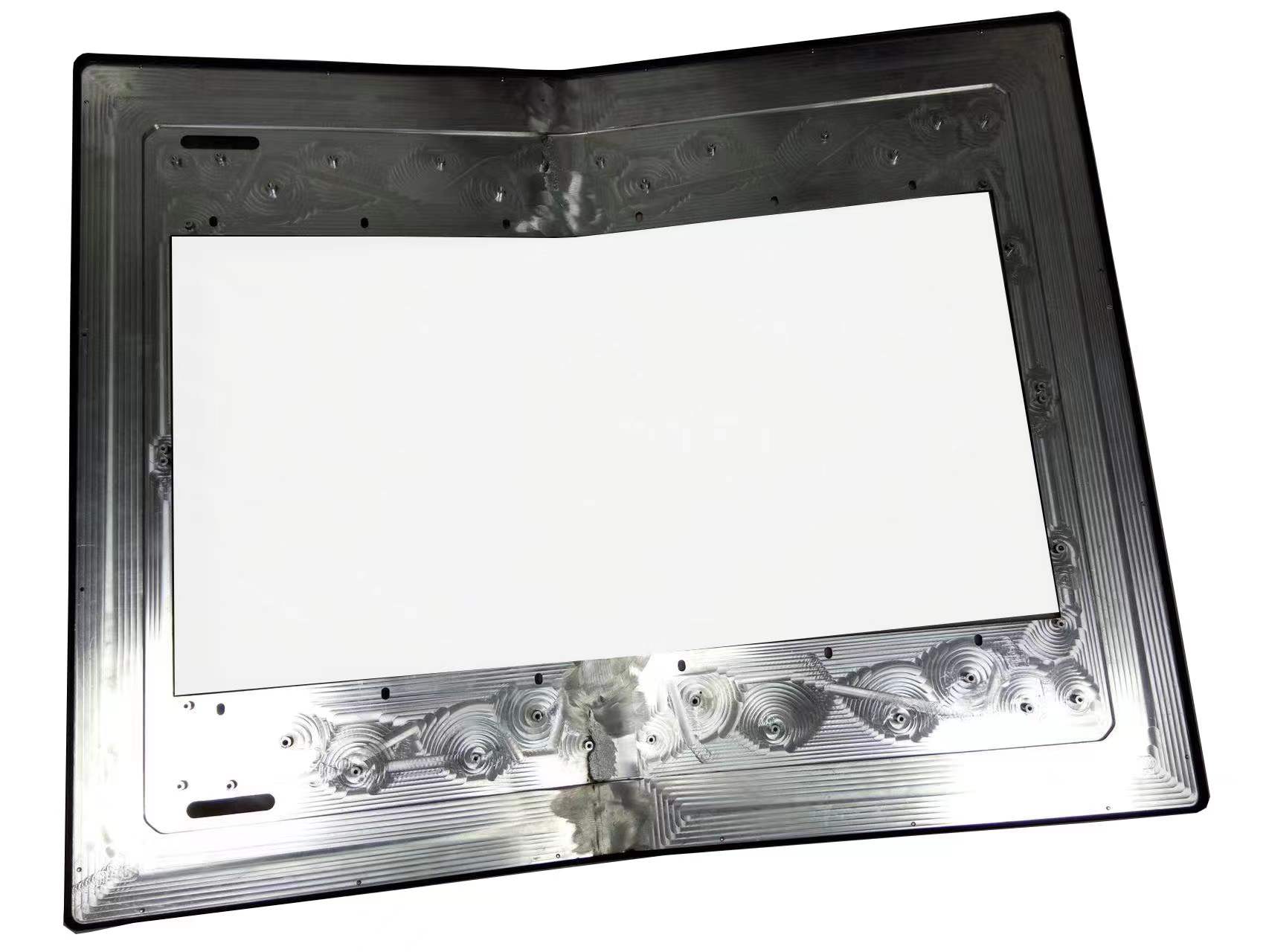

Lidar IMUX-SP1 Box

According to your project needs, CNC service can solve various problems for you. If you would like to know more about technology and prototyping services, please call us. We are glad to provide you with professional and efficient service.

- Material Used:Aluminum alloy 50552

- Number of Cooperation:3 sets total 3

- Production Process Used:Sheet metal bending, riveting, welding, Alodin chemical conversion, surface spraying, silk screen printing

- Production Cycle:10 days

Project Details

About Product and Design Requirements

This is a world-renowned high-tech company from Israel, specializing in the production of automotive solutions. This product is used in the design of protective boxes for automotive laser radar equipment. It needs to have good internal conductivity, surface corrosion resistance, and strong edge structure.

Customer Demand

After in-depth discussions with customers and the characteristics of the materials, we use sheet metal bending + welding screws to use riveting, and the surface is produced by the process of Alodin chemical conversion and spraying to reduce the production cycle and improve the product cost-effective advantage.

Detection Method

It needs to pass a strict three-dimensional coordinate test. The processing size error marked on the drawing does not allow one unqualified. It must meet 100% of the customer's design requirements, and the number of sizes to be tested reaches 300.

About the Project

Through cost accounting and process analysis, we have worked out CNC turning + CNC milling coordination + high-precision positioning tooling and fixtures. After a variety of supplier evaluations, the customer finally chose to cooperate with us.

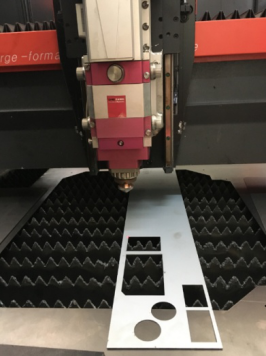

Sheet Metal Bending

Before the sheet metal is bent, the parts need to be unfolded on a flat surface, and then the unfolded appearance of the product is processed on the CNC laser cutting machine. The power of our CNC laser cutting machine exceeds 3000W, which can easily cut 10mm thick plates with precise control of 0.05mm.

High-quality CNC bending equipment and experienced engineers can control the accuracy of the bent parts within 0.05-0.1mm and the angle within 0.5 degrees to ensure that the dimensions of the parts are qualified.

The R angle of the edge of the product appearance is beautiful and consistent, which is too inseparable for skilled polishing techniques.

Alodine Chemical Transformation

The chemical transformation of Alodin's natural color can perfectly isolate the surface of the aluminum alloy material from the gas and liquid in the environment, and it can resist corrosion. At the same time, it can also make the parts have good electrical conductivity and meet the electrical conductivity requirements between the parts. The chemical transformation of Alodin can meet the needs of a variety of colors, including natural colors.

Surface Spray

We have professional surface spraying, including painting and electrostatic powder spraying, to achieve a more beautiful appearance of the product.

Quality Inspection

The inspection of dimensions and details can reflect the degree of professionalism. Do a good job in the inspection of details to improve customer satisfaction.

Experience

Only with professional technology and strict control of precision can we produce final products that satisfy customers. We are proud of every part we produce. You will be proud of having these customized parts. If you have a project, please contact us in time to customize a solution to meet your needs.