The engineer will flatten it into a 2D plane shape based on the 3D drawing by using the software. The second step is to perform laser cutting according to the 2D unfolded drawing. According to the size of the 3D drawing, install the correct bending tool on the bending machine, and perform each step of the bending according to the standard of the 3D drawing through a strict process until the production is completed. Commonly used processes for sheet metal prototypes include laser cutting, stamping, welding, riveting, polishing, and post-processing processes such as surface drawing, electroplating, anodizing, and spraying.

Why make rapid prototypes

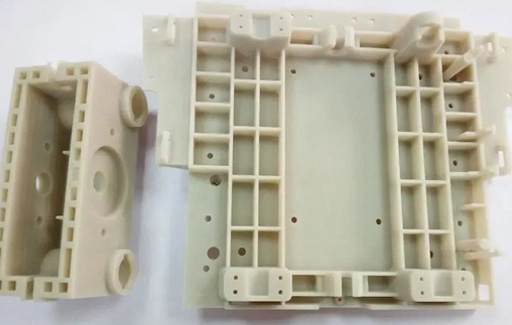

Rapid prototyping is a production technology such as CNC machining, 3D printing, and vacuum compounding, which converts the theoretical design of 3D drawings into actual samples. The prototype can be of appearance or structure type. The prototype is characterized by its intuitiveness and fast production, saving customers valuable time and cost.

Through a good prototype, the engineering designer can quickly verify the initial design idea, and verify the appearance and structure to provide a basis for subsequent modification of drawings.

Rapid prototyping can shorten the working time before product sales, and can directly produce rapid prototype products for the first promotion, and prepare for seizing market opportunities.

Before mass production of molds, in order to reduce the risk of high-cost investment in molds, rapid prototyping is a necessary part of the final market verification. If you have any needs for rapid prototyping, please contact us in time. We can provide you with a free consultation.